Please enter the key words you searched first…(Example:Ship unloader,Ship loader,Industry)

Solutions

ATXL continuous screw ship unloader is a powder material unloader specially developed by the company for domestic and foreign cement related enterprises, and it is also the longest and earliest developed equipment in the company's research and development history. It can be used for unloading cement, GGBS, fly ash and other similar materials. After more than ten years of development and renewal, the equipment has now achieved semi-intelligent production, no dust overflow in the whole production process, and has a strong continuous high-yield unloading capacity ( 200t/h to 1500t/h ).

When selecting equipment, the supplier shall be informed of the name and main physical and chemical properties of the materials to be delivered, such as whether there is corrosivity, particle size, bulk density, moisture, etc.

TXL continuous screw ship unloader is a three-coordinate ship unloader, consisting of a vertical screw conveyor, a horizontal screw conveyor, a discharge conveyor, a dust remover, a dust remover, a horizontal arm, a counterweight, a bracket, a hydraulic station, an electrical control and accessory equipment components, etc. It uses the tubular structure of the vertical screw conveyor and the horizontal screw conveyor and the high-efficiency conveying function to integrate it with the arm erection capable of three-dimensional movement into a whole walking on the track, and enables the material picker to track the material position by operating the handle of the movement control box, and automatically unloads the materials in the cabin to the transportation system or material tanker on the shore. According to the actual process in the field, the main engine of the screw unloader can be installed on various vehicles such as fixed foundation, gantry crane, frame, ship, etc. to finally meet various working conditions.

The feeder with double inlets extends into the cement while rotating, the surrounding loose cement ( or other powder ) is brought into the cavity and compacted to a certain extent, and the vertical screw shaft extending into the feeder cavity rotates at a reasonable speed to lift the cement to the discharge port at the top of the lower section, the discharge port is connected with the feed port of the upper joint section, the cement enters the upper joint section of the vertical screw conveyor, and its discharge port is connected with the sealed feed port of the horizontal conveyor. After entering the horizontal conveyor, cement is conveyed to the discharge port of the horizontal screw conveyor through the discharge cylinder cement into the discharge pipe, and then enters the rotary dynamic sealing discharge port inside the door machine column by the self-weight of the cement, which is connected with the feed port of the discharge conveyor, and cement is conveyed to the discharge telescopic head by the discharge conveyor and enters the feed port of the belt conveyor or the material tanker. The whole flow process is sealed to ensure that no dust escapes from the material.

The flow of the lower section of the vertical screw conveyor can be adjusted within a certain range. The upper joint section of the vertical conveyor and the horizontal conveyor are fixed flow and the flow of the discharge conveyor, while the flow of the latter is larger than the maximum flow of the former.

The basic principle of the material flow between the vertical screw and the outer pipe is the axial force component of the blade to the material when the screw blade rotates. When the material flows vertically upward, it must also be supported by sufficient radial centrifugal force.

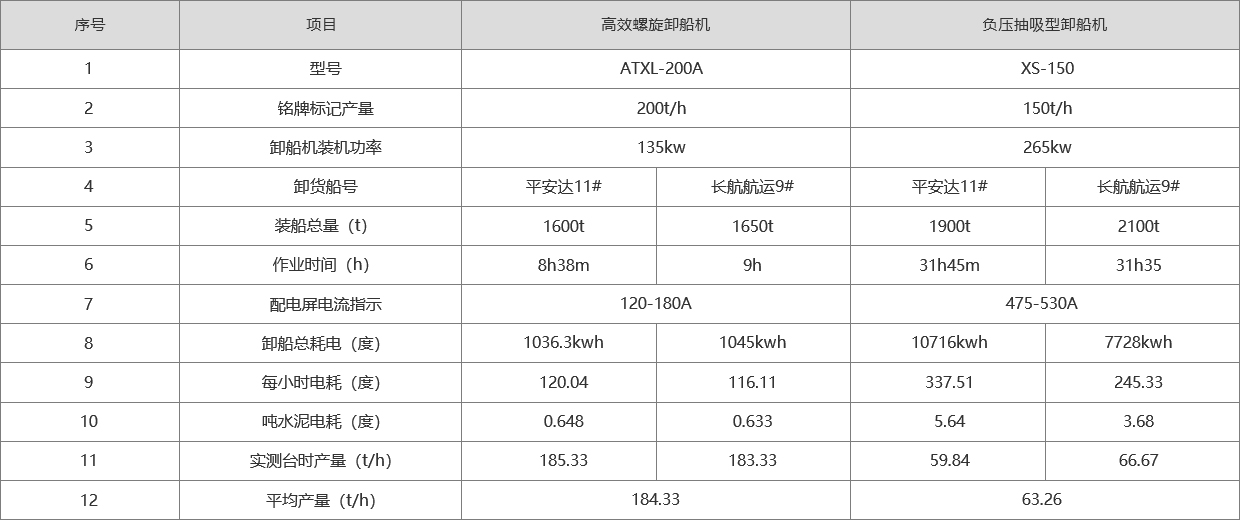

Description: In order to compare the actual output and power consumption of the two types of ship unloaders, the company organized technicians to carry out field measurements of ATXL-200A high-efficiency vertical screw ship unloader and a negative-pressure suction ship unloader installed in adjacent docks at Wenzhou Ruian Wharf in 2006.

• Survey time: It started at 7: 30 on March 25, 2006 and ended at 10: 50 on March 29, 2006. It lasted 75 hours and 20 minutes. There is a break interval between them

• Survey object: Two ships are used, one is Pinganda 11 # ship and the other is Changhang 9 # ship, all of which are 2000dwt bulk cargo open-ended ships. Negative pressure suction ship unloader and screw ship unloader respectively unload the two ships.

• Conveying material: 2.5 ordinary portland cement

The following is a comparison of two types of installed data and field measurement data:

The measured output of the screw ship unloader is close to the real output of the marking station, and the nominal output of the negative pressure suction ship unloader is much higher than the measured output, with a large deviation.

The cement electricity consumption of screw ship unloader is about 1/8 of that of negative pressure suction ship unloader.

The screw ship unloader can complete the unloading of a ship in less time.