Please enter the key words you searched first…(Example:Ship unloader,Ship loader,Industry)

Solutions

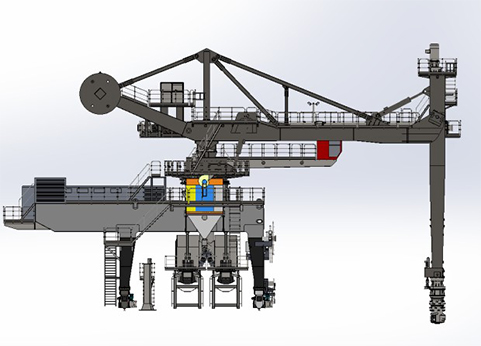

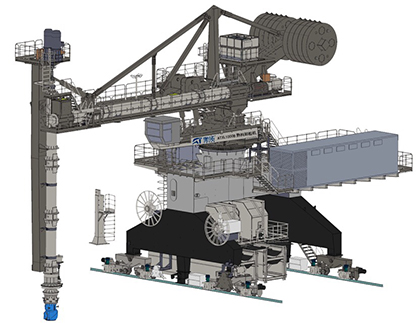

Cement clinker is a semi-finished product obtained by using limestone, clay and iron as main raw materials, preparing raw materials according to proper proportion, burning to partial or complete melting, and cooling. In the cement industry, the most commonly used portland cement clinker mainly consists of calcium oxide, silica and a small amount of alumina and iron oxide. The main mineral compositions are tricalcium silicate, dicalcium silicate, tricalcium aluminate and tetracalcium ferric aluminate. Portland cement clinker is grinded together with a proper amount of gypsum to form Portland cement. General clinker ( particle size 5~10mm, powder grain ) is 1.2 ~ 1.4 tons / cubic meter. For the screw ship unloader, the clinker has poor fluidity and strong grindability, and the requirements on the wear resistance and reliability of the ship unloader are very strict.

With the rapid development of the logistics industry, the loading and unloading of bulk materials ( clinker, ore, lump coal, etc. ) has greatly increased. At present, there is no effective closed unloading method for clinker at home and abroad, with short service life and high price. Most of the sources and receiving points of clinker are distributed in inland river terminals. In recent years, the market demands more and more environmental protection and energy saving, so the continuous closed discharge mode has become the market trend. Aotuo aims at this material and cultivate it into a fist product in the new stage of the enterprise. On the basis of further consolidating the market position of the enterprise, with the help of the influence of the enterprise brand in the industry, it will further establish a new competitive advantage and market position.